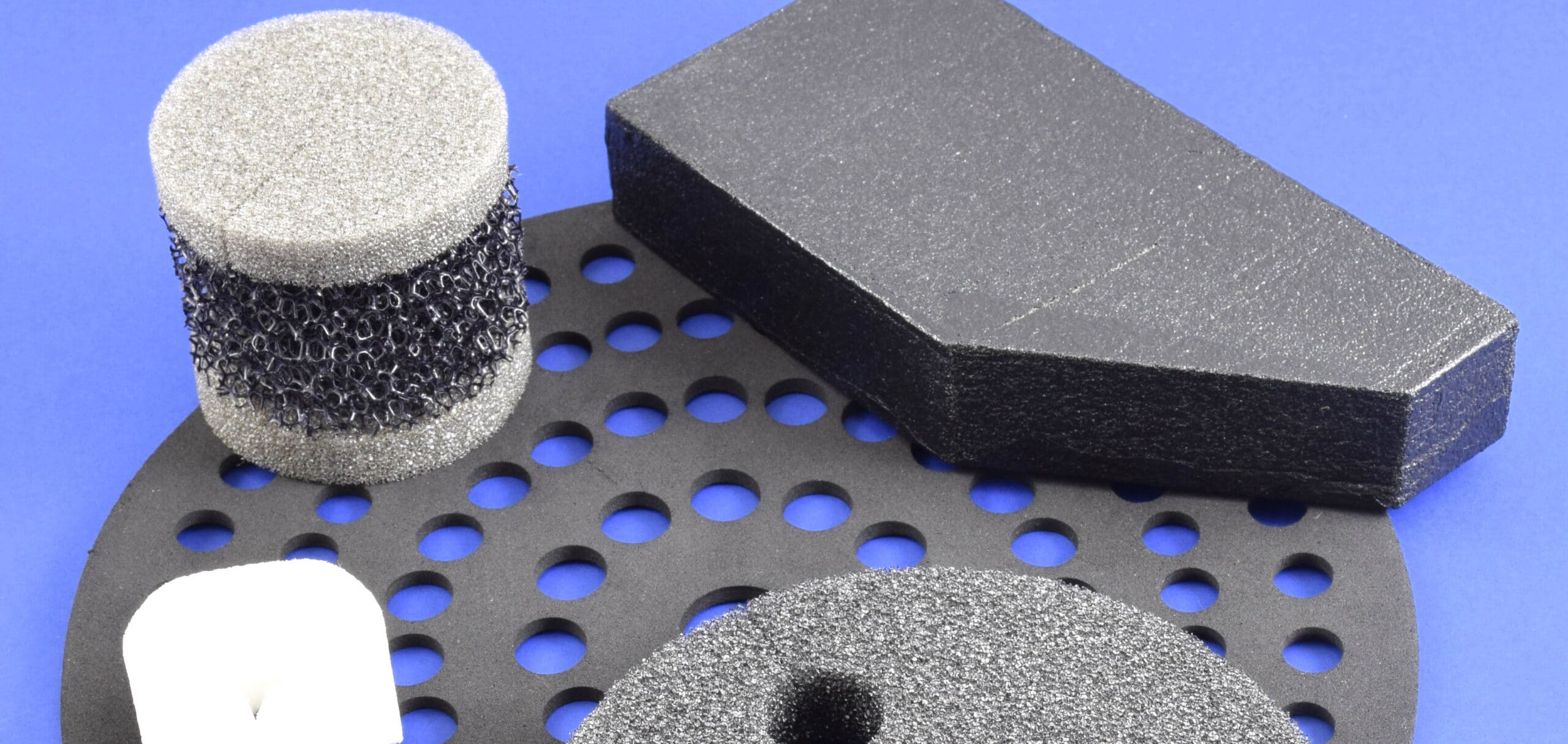

Many products require flexible materials like silicone foam, rubber, and more. From gaskets to bumpers/cushions to insulators, the possibilities are vast. But what characteristics need to be taken into consideration when choosing materials to use in your products?

While there’s no one-size-fits-all solution in manufacturing, here are a handful of important factors to evaluate when choosing your flexible materials:

- The ability to withstand both high and low-temperature extremes.

- Whether or not it can protect electronic components from destructive electromagnetic interference (EMI) or radio frequency interference (RFI).

- Resistance to chemicals, especially when used in gaskets and seals.

- Compatibility with adhesives.

- Deflection of water and air.

- Flame resistance.

- Pressure handling.

- UV and Ozone exposure resistance.

- Vibration handling and absorption.

- Contamination blocking.

- Compression force absorption.

- Insulative capability in regards to electronic/electromechanical equipment and acoustical insulation.

- Conformability to any size space.

- Thermal conductivity.

While all of these factors are important, they’re not all required for every product. To determine which are necessary for your items, please contact our materials engineers for a consultation!

Get Your Free Quote on Flexible Materials

American Flexible Products is a nationwide converter of flexible materials—from foam to rubber to silicone and more. Every product is custom-cut and shaped to your design specs by our materials engineers.