Flexible materials vary. It’s important that the right flexible materials are used for each application. The product may need extra dimensional stability, sound insulation characteristics, higher tear strength or the ability to be used in extreme temperatures.

BISCO® silicones are meant for high performance. Some characteristics of these flexible materials include flame resistance, resistance to ozone and UV radiation, sound insulation and chemical resistance. Here are three types of BISCO silicones and their advantages.

1) Bun Silicones

Ideal for repeated, long-term use in private and mass-transit passenger seating. It has low compression set resistance, high-performance FST features, high resistance to extreme weather. Bun silicones are great for long-term comfort in cushioning applications.

2) Cellular Silicones

These open cell and closed cell materials have compression set resistance for long-term sealing. Cellular silicones can withstand temperatures from –67°F to 392°F and meet the most stringent UL-94 flame ratings available: V-0 and HF-1.

3) Solid Silicones

These types of BISCO silicones come in the form of general-purpose solids and performance solids. General-purpose solids are available with fiberglass reinforcement and a range of durometers from 40-70 Shore A.

Performance solids offer tight tolerances and softness, which are ideal for demanding sealing applications. Performance solids are usually available in a range of durometers from 10-40 Shore A.

Need Custom-Fabricated Bisco Silicone? Talk to an Expert Today!

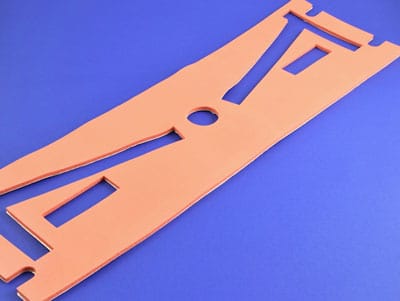

American Flexible Products is a nation-wide converter of flexible materials—from foam to rubber to silicone and more. Every product is custom-cut and shaped to your design specs by our materials engineers.

We are an official Preferred Converter of products from Rogers Corporation, which allows us to custom-fabricate Rogers’ BISCO® Silicone products. Call 952-368-4225 and our material experts will help you choose the right grade, size and shape for your prototype.